What is pre-applied masking film?

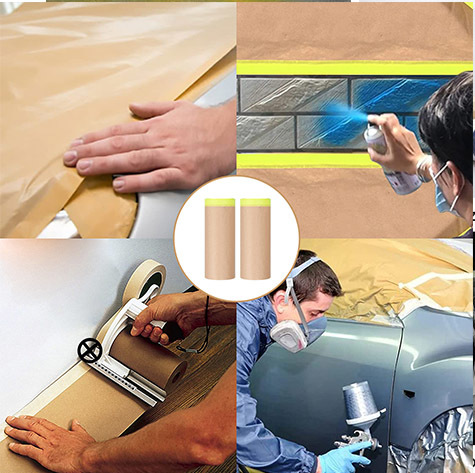

Pre-applied masking film is a specialized protective material that consists of a thin plastic film (usually made of polyethylene) or kraft paper pre-applied to a tape that can be applied quickly and efficiently during surface treatment. It is mainly used in renovations and automotive painting processes. The product is designed to protect surfaces from overspray, dust and damage, while ensuring clean and sharp edges during the painting or coating process.

Main applications

1. Automotive painting and repair

Pre-applied masking film is widely used in automotive repair shops to protect non-target areas during the painting process. For example, it protects car windows, interiors and headlights from paint overspray while accurately masking complex curves and edges. Its low-residue adhesive ensures that delicate surfaces such as glass or polished metal are not damaged.

2. Industrial manufacturing

In industries such as electronics, this film protects sensitive components during the coating process. For example, it protects circuit boards from solder splatter or protects mechanical parts during chemical treatment.

3. Furniture and construction

Carpenters and builders use it to protect floors, walls and fixtures during the painting or varnishing process. Its durability withstands wear and chemical attack, making it an ideal choice for large projects.

Advantages of masking film over traditional masking materials

1. Unlike traditional masking tapes that require manual alignment, pre-laminated films combine tape and film into one roll. This eliminates the need for separate materials and can reduce setup time by up to 50%.

2. The flexibility of the film can conform to irregular shapes, such as the edge of a car door or curved furniture edges. Advanced versions have anti-curl properties to prevent edges from lifting during the painting process.

3. Companies can save on material costs by avoiding paint contamination and reducing rework caused by spraying errors. Abendo masking film provides bulk pricing for industrial customers as an industry-leading supplier.

4. Many films meet EU and international safety standards, use low-VOC adhesives and recyclable materials. For example, brands such as AUTOHAUX emphasize environmentally friendly production processes.

Industry Trends and Innovations

1. Customization. Manufacturers now offer films in different widths (e.g. 50mm-2700mm), thicknesses and lengths to meet specific needs. Some films also include UV-resistant coatings for outdoor applications.

2. Smart masking solutions

Emerging products integrate multiple features, such as high temperature resistance (up to 160°C) for automotive baking processes, or anti-static properties for electronics manufacturing.

3. Global market growth

Demand for pre-laminated masking films is growing in regions such as the Middle East and Southeast Asia, driven by the expansion of the automotive and construction industries. Chinese suppliers dominate the export sector, and platforms such as Amazon, eBay and Alibaba facilitate global distribution.

How to choose the right pre-laminated masking film

1. Material compatibility. In industrial environments, choose high-density polyethylene (HDPE) or polyethylene (PE) films for chemical resistance. Kraft paper masking films have good anti-permeation properties and temperature resistance. For delicate surfaces, choose low-viscosity adhesives to avoid residue.

2. Size and bonding strength, choose the film width according to the scale of the project - narrower films (35 cm) are suitable for small parts, while wider rolls (150 cm) are suitable for vehicles or mechanical equipment.

3. Environmental protection, kraft paper masking film is usually made of recyclable materials and has environmentally friendly and non-polluting characteristics. It can be recycled and reused after use, in line with the requirements of sustainable development

4. Ensure compliance with industry standards such as ISO 9001, CE or REACH

Conclusion

Pre-laminated masking film combines efficiency, precision and sustainability, and is revolutionizing surface protection in all walks of life. From automotive refinishing to high-tech electronics manufacturing, its versatility can meet various challenges in modern production. As innovation continues to advance, expect smarter and more environmentally friendly solutions to dominate this dynamic market.

Keyword:

Pre-laminated masking film,industrial masking solutions,Environmentally friendly masking film

RELATED NEWS