Rewinding

What Is Tape Rewinding?

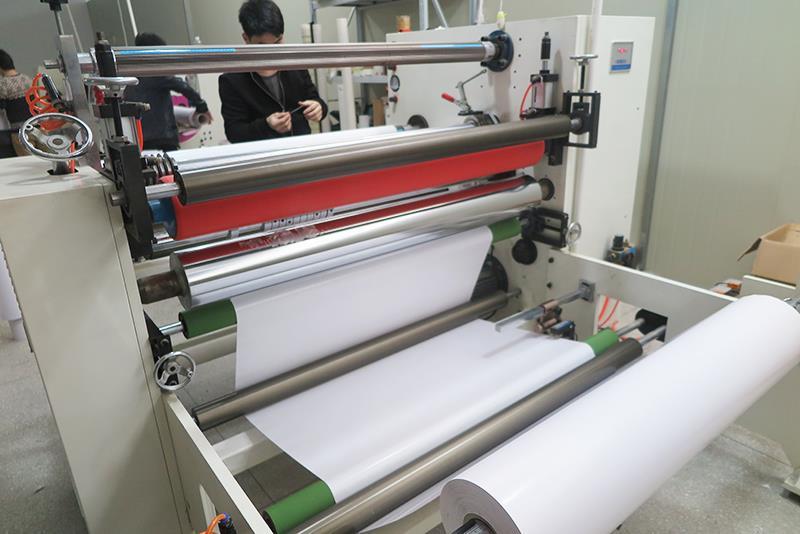

Rewinding is a critical post-production step in tape manufacturing that involves transferring semi-finished tape rolls (e.g., laminated or coated materials) onto smaller, customer-ready spools or cores. This process ensures uniform winding tension, alignment, and dimensional accuracy, making tapes easier to handle and apply in industrial or consumer settings

Key Steps in the Rewinding Process

1. Material Preparation

- Input: Semi-finished "jumbo rolls" from coating or laminating stages

- Core Loading: Empty spools or cores are loaded onto the rewinding machine. Materials like paper, plastic, or metal cores are chosen based on tape type (e.g., heavy-duty tapes use steel cores)

2. Unwinding & Tension Control

- Unwinding System: The jumbo roll is mounted on a motorized shaft, and tension is controlled to prevent stretching or wrinkling. Modern systems use floating rollers or torque controllers for real-time adjustments

- Critical Parameters:

- Tension: 0.5–2.0 MPa (varies by tape thickness)

- Speed: 50–200 meters/minute

3. Slitting & Alignment

- Slitting Blades: High-precision rotary blades cut wide jumbo rolls into narrower strips (e.g., 12mm, 24mm)

- Edge Alignment: Laser sensors or vision systems detect misalignment (±0.2mm tolerance) and trigger automatic corrections

4. Rewinding & Compression

- Winding Modes:

- Surface Winding: Pressure rollers ensure tight, bubble-free layers (ideal for thin films like BOPP)

- Center Winding: Motor-driven cores maintain tension for heavy tapes (e.g., fiberglass-reinforced tapes)

- Layer Counting: Automated counters track tape length with ±3m accuracy

5. Quality Inspection

- Defect Detection: Optical scanners identify bubbles, wrinkles, or adhesive leaks

- Performance Tests:

- Peel Strength: ≥5 N/cm (ASTM D3330)

- Width Tolerance: ±0.5mm

6. Packaging & Labeling

- Finished rolls are wrapped in anti-static film or boxes, labeled with specifications (width, length, batch number), and palletized for shipping

Industrial Applications of Rewound Tapes

| Industry | Use Case | Key Requirements |

|---|---|---|

| Electronics | Lithium battery terminal insulation tapes | High alignment precision (±0.2mm) |

| Packaging | Fiberglass-reinforced strapping tapes | Tensile strength >200 N/cm |

| Construction | Double-sided acrylic foam tapes | Uniform adhesive distribution |

| Healthcare | Medical-grade silicone tapes | Contamination-free winding |

Common Challenges & Solutions

| Issue | Cause | Solution |

|---|---|---|

| Edge Curling | Uneven tension or blade wear | Replace blades; optimize tension control |

| Layer Slippage | Insufficient compression | Increase roller pressure |

| Static Buildup | Friction in synthetic films | Install ionizing bars |

Future Trends

- Automation: AI-driven systems for real-time tension and alignment adjustments

- Sustainability: Recyclable cores and solvent-free adhesives to reduce waste

- High-Speed Rewinding: Up to 500 meters/minute for mass production

Conclusion

The rewinding process bridges large-scale tape production and end-user practicality. By integrating precision slitting, tension control, and smart quality checks, manufacturers can deliver tapes that meet rigorous industrial standards while minimizing material waste. Innovations like IoT-enabled rewinding machines and biodegradable cores will further revolutionize this field

Office: Building 2, Houdequn Creative Industrial Park,Shajing Town, Baoan District, Shenzhen,Guangdong, China.

Factory: Building 7 of Liandong U Valley, No.510 Xihuan Road, Houjie Town, Dongguan, Guangdong, China.

Copyright © 2021 abendo All rights reserved.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

LET'S GET IN TOUCH