Die cutting

What Is Die-Cutting in Tape Production?

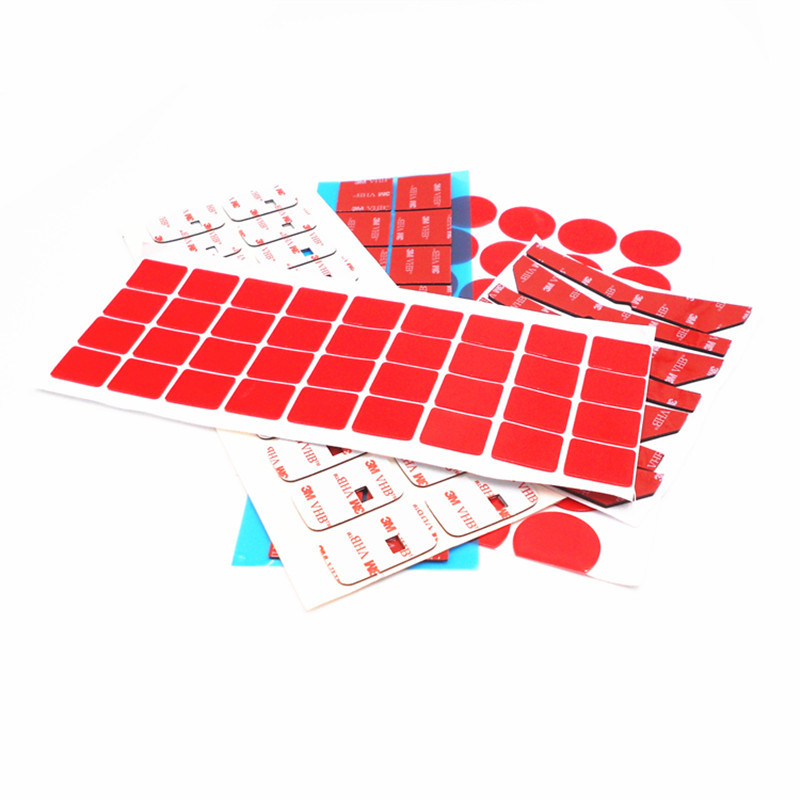

Die-cutting is a precision process used to create custom-shaped adhesive tapes from laminated or coated materials

This technique employs steel blades or laser systems to cut through tape layers, producing components with exact dimensions for specialized applications like medical devices, electronics, and automotive parts

Die-Cutting Techniques in Tape Manufacturing

1. Flatbed Die-Cutting

- Process: Uses a hydraulic press with fixed steel rule dies to cut static materials.

- Applications: Ideal for thick foam tapes or multi-layer composites requiring high-pressure accuracy

2. Rotary Die-Cutting

- Process: Cylindrical dies rotate synchronously with material feed, enabling high-speed cutting (up to 200 meters/minute)

- Advantages: Best for high-volume production of uniform shapes (e.g., battery insulation tapes)

3. Laser Die-Cutting

- Process: CO2 or fiber lasers vaporize tape layers with micron-level precision (±0.1mm)

- Benefits: Zero tool wear, ideal for heat-sensitive films like polyimide or conductive tapes

4. Semi-Cut vs. Full-Cut

- Semi-Cut: Only penetrates the adhesive layer, preserving backing material (e.g., medical tapes with release liners)

- Full-Cut: Cuts through all layers for standalone components like EMI shielding gaskets

Key Steps in Die-Cutting Workflow

-

Tool Preparation

- Design CAD-based templates for steel rule or laser tools

- Select blade hardness based on tape material (e.g., carbide blades for abrasive glass fiber tapes)

-

Material Feeding

- Align laminated tapes using auto-centering guides to minimize waste

- Apply tension control (0.5–2.0 MPa) to prevent wrinkling or stretching

-

Cutting & Ejection

- Use vacuum systems or ejection pins to remove cut parts without residue

- Use vacuum systems or ejection pins to remove cut parts without residue

-

Quality Inspection

- Optical Scanners: Detect edge burrs (>0.2mm) or misalignment

- Peel Tests: Verify adhesive integrity (≥5 N/cm per ASTM D3330)

Common Challenges & Solutions

| Issue | Cause | Solution |

|---|---|---|

| Edge Burrs | Dull blades or high speed | Replace with ceramic-coated blades |

| Adhesive Residue | High-viscity adhesive | Use Teflon-coated tools or serrated blade |

| Material Tearing | Incorrect blade pressure | Optimize hydraulic pressure (1.5–3.0 MPa) |

Industry Applications

- Electronics: Laser-cut FPC tapes for flexible circuits

- Healthcare: Hypoallergenic wound care tapes with half cut precision

- Packaging: Custom-shaped biodegradable sealing tapes

Future Trends in Die-Cutting

- AI-Driven Optimization: Machine learning adjusts cutting parameters in real-time to reduce defects

- Sustainable Tooling: Recyclable steel blades and water-based adhesive tapes

- Hybrid Systems: Combine laser cutting and embossing for smart tapes with embedded sensors

Conclusion

Die-cutting bridges design innovation and functional performance in adhesive tape production. From automotive EMI shielding to medical-grade adhesives, this process ensures precision while minimizing material waste. Advances like laser systems and AI quality control are driving efficiency and sustainability in the industry